| CONTENTS:

TK560 Main

Communicators

Phasers

Tricorders

Helmets

Blasters

Stormtrooper Armor

Lightsabers

Astro-Mech Droids

How-to Guides

Cylon

Centurion

Viper Pilot Helmet

M41-a Pulse Rifle

Motion Tracker

B5 PPG

Retro

Box Designs

Repair/Restoration

Replica Parts

40th Anniversary

Replica

Weapons/Gear

Reenactment Units

ME262 Project

Civilian

Marksmanship Program |

M1

Garand Rifle

M1903 Springfield

Rifle

M1 Carbine

Discussion

Board

Lauren Photo Albums

Egner II

Design

Please

note, that the images, logos, and respected artworks, are property of

the original copyright owners. TK560 has no affiliation with any of the

intellectural property owners. This is a fan site dealing with movie and

television replica props, original GIjOE action figures, World War II

memorbilla, and marksmanship/ firearms interests. Most of the images used

on this site are photgraphed by the site owners. Official logos are used

to identify specific products/ manufacturers.

|

The finished

MK I helmet.

Note: a second

"improved" helmet kit is under construction. Check back

soon for updates to this "hero" version of the prop.

|

Cylon

Centurion Helmet

Another

great sci-fi prop to add to your collection. By your command.

First

of all, I'd like to say that it was years since I've seen Battlestar

Galactica, [until the DVD set was released in October] and when

I began research on this project, I was delighted to find that there

was "alive and well" BSG community on the internet. I

wanted to build a complete costume, like I did with my Stormtrooper

uniform. Unfortunately the cost for a "real" or "official"

one was prohibitive. I decided to start with just the helmet, [as

I did years ago with my Stormtrooper]. I searched several options,

fiberglass, resin, and vac-u-formed plastics, before choosing on

a vac-u-form styrene/resing kit. The following is a work in progress

that details the build up of this prop replica. Please note, I'm

not a big fan of "sending off" my stuff for others to

complete, even having a pro shop do the chrome plating, just so

you would know. Also, under the PAINTING

section, I have my experiments of different off-the-shelf chrome

options and techniques available for comparison.

The

kit is one of those "unofficial" versions, as there are

no known officially liscensed helmet only kits on the market. Check

the LINKS page for official BSG merchandise.

Click here

to request the source of the helmet by email. |

| Parts |

|

The kit arrived

from the online seller in quick fashion, and was $65 plus shipping.

Now, for anyone who has never dealt with unofficial or garage made

kits, these things can be a little rough as compared to a commercially

produced piece. I was pleasantly surprised. The kit, although a

simple 4 part job, was fairly symentrical, and the vac formed plastic

moulds had cut lines as guides. The resin "eye" is less

symetrical and had numerous casting flaws. The "mouth"

piece was at first glance dissapointing, but furthur research revealed

there were originally 2 types of "mouths" , the one in

the kit is a "background' version.

|

| Materials |

Well,

the styrene kit needed to be trimmed, glued primed painted and chromed.

The following is my list of needed parts or supplies to finish this

kit:

|

|

Sharp

hobby knife [X-acto]

Sand

paper in various grits from medium to extra fine

Steel

wool 0000

Super

Glue and accellerant

Sharpie

fine tip marker

Body

filler glazine putty [Bondo spot putty] red kind

foil

type metal duck tape

Flat

spring type clamps

ruler

|

Takck

cloth

Primer

paint [gray or white]

Dark

gloss machine gray spray paint

Ultra

flat black spray paint

Glossy

Black for chrome undercoat

Gray

foam or Hard hat liner [optional]

2

part resin for building up the visor, JB quick weld or similar 1:1

resign will do.

electronics

for eye

electrnic

for warble and cylong voice |

| Building |

| The

following is a photo gallery detailing the building process. Please

note, this is not the only way to build the kit, and I used a lot

of liberty in making this one. Again, I tried to use hardware store

or auto parts store materials instead of special mail order stuff. |

|

|

|

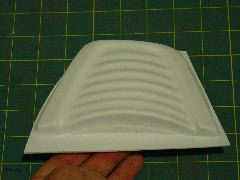

| Image

1 shows the kit as received from the seller. Note the instruction

sheet, visor and mouth pieces. |

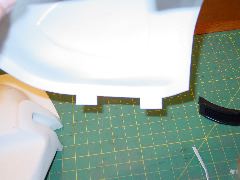

Image

2 shows the amount of trimming needed to get started. The

visor area, will be done last. |

Image

3 shows the non symetrical visor part. this will require

some build-up to make work. |

|

|

|

| Image

4 shows the mouth part, and is the "background type,

with less defined "vents". |

Image

5 shows a trimmed helmet half on the right and the as received

one on the left. Note the amount of trimming around the bottom of

the helmet. |

Image

6 details the "mohawk" trim. Note, the mouth area

and visor are not yet trimmed. |

|

|

|

| Image

7 details the final trim without the visor slot cut. |

Image

8: The next step required the two halves to fit together

and hold its shape. Since these two halves do not overlap, and controling

the contact points needed to be considered, I decided at this point

to make my helmet a one piece unit. |

Image

9 I cut small strips of styrene from the excess trim materials,

and super glued them to make fingers. alternating them on each side

of the helmet halves. |

|

|

|

| Image

10 shows one side... |

Image

11 shows the other side... |

Image

12 shows that when fitted together the helmet starts to take

shape. |

|

|

|

| Image

13 details the inside of the helmet. Note how the finger

strips inter mesh to hold its shape. |

Image

14 shows the parts of the kit up to this point. |

Image

15 shows the body filler applied to smoothe out the resin

visor casting flaws. |

|

|

|

| Image

16 shows the non-symetrical shape of the twos parts. This

was discovered after the two halves were gluded together. |

Image

17 shows masking tape applied to the inner side seam, to

act as a backstop for the body filler. |

Image

18 shows the body filler applied to the seam. Several layers

will be required. |

|

|

|

| Image

19 shows the body filler used to hide the seam. Note the

top is not even, and will require a build up. I kinda like the red

"mohawk"! |

Image

20 shows another view of the body filler applied. Styrene

is very easy to use and will take a lot of abuse before a repair is

necessary. Look-out though, styrene will melt and distort in hot weather

and is subject to melting with certain chemicals like finger nail

polish remover. |

Image

21 I needed to extend the "nose bridge" section

about 3/4". So I built up a small form from hobby clay, masking

tape and carboard, mixed some Bondo and poured it in the form. Bondo

will set up in a few minutes, and was ready to sand. |

|

|

|

| Image

22 shows the backsideof the nose bridge extension, I reinforced

it with a strip of styrene from an old garage sale sign. Just super

Glue it into place. |

Image

23 shows some final sanding and some additional surface pinhole

repairs. Note the top portion, it needs to be more level, the left

side is considerably thinner than the right side. |

Image

24 shows a close up of the addition. Almost ready to paint.

There needs to be some additional material added to the top left portion

of the visor. |

|

|

|

|

Image

25 shows the primer gray paint before a ultra flat black

top coat is applied. Note, the leftside has been rebuilt, using

a simple masking tape form, and Bondo then sanded to conform to

the final shape. |

Image

26 shows the painting of the ultra Flat black paint still

wet. The flash from the camera makes the black look glossy. It is

not. |

Image

27 shows the helmet shell ready for final primer coat. A

lot of defects will be revealed with the gray primer. |

|

|

|

| Image

28 this is what the first coat of gray primer looks like.

Not bad, but some rough spots will need to be addressed. 2 more primer

coats will be necessary. |

Image

29 shows the mouth portion with the first of the two primer

coats. The finish coat will be a machine grey glossy with a Plasticote

Charcoal Gray topcoat dusting. This will simulate a gun metal finish. |

Image

30 shows final smoothing and defect filling using the body

filler. A final topcoat of primer will be added. On to chrome painting. |

|

|

|

| Image

31 shows the initial application of the Krylon Original Chrome

paint. Not as shiney as real chrome, but will work for this project.

Several coats will be applied, and a final glossy topcoat will be

added to give it a little more shine. |

Image

32 shows the second coat of chrome paint. |

Image

33 Adding the mouth vent. |

|

|

|

| Image

34 Marking the position of the visor. |

Image

35 making some tension splints for holding the visor. |

Image

36 masking for final accent color with a low stick masking

tape to define the outline. |

|

|

|

| Image

37 painting the accent color a flat black. |

Image

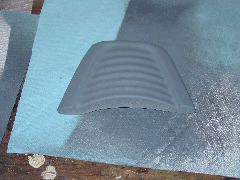

38 final product without electronics. |

Electronic

eye and "warble" sount to be added later. |

NOTE:

Bondo is a trade name as is used for gthe generic term Two-Part Polyester

Resin Auto Body Filler.

Super Glue is a trade name for Cyroacryllic glue

Xacto is a trade name Precision Hobby Knife.

Painting

I'm

a big fan of Krylon. Rustoleum is

ok, but the control of the Krylon for me works better. Below is the results

of several "spray chrome" paints. The Krylon "Original

Chrome" gives the best effect, but must be sprayed from a close distance,

no more than 4-6 inches from the surface, and every last trace of dust

will show up. Also, I have noticed the surface will release easily if

masking tape is applied. So when painting the rear indent areas, you might

want to do them first, mask the them, then paint the chrome last.

The

kit gets 2-3 coats of Krylon Sandable Gray Primer

The

visor gets 2-3 top coats of Krylon Ultra Flat Black

The

Mouth gets 2-3 top coats of Krylon Machine Gray and a dusting of Plasticote

Charcoal gray auto body paint.

The

helmet shell gets one heavy coat of Krylon Original Chrome

The

helmet indents get 1-2 coats of Krylon Ultra Flat Black

Let

the helmet dry for several days. The chrome will lift, and there will

be some fingerprinting. Only other option is a Pro Shop Chroming service.

Price Range is $80 to $150 for the shell. Ouch!

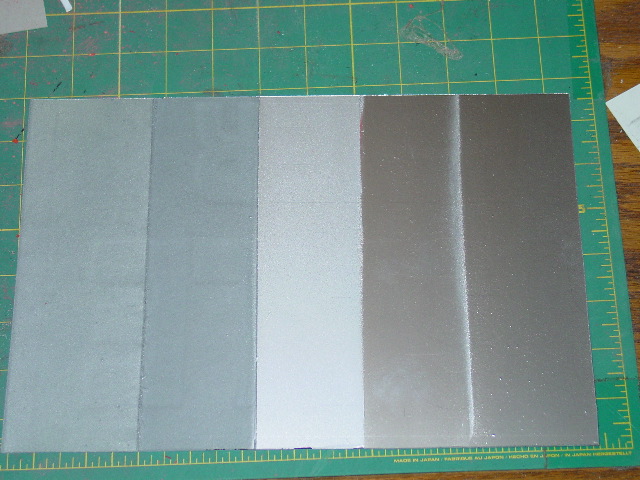

Here

is the chrome finish samples:

I prefer

the one on the far right, the Krylon Original Chrome, next to that one,

is Krylon's short can of chrome, in the middle is Rustoleum Spray Silver,

and on the left, is the Krylons with a polyurethane topcoat, yuck.

Finishing

Detailing

this project consisted of superglue-ing the mouth piece to the front,

and mounting the visor. I wanted to remove the visor part in the future

so that I could add electronics, I tension bracked mounting system was

devised with strips of styrene.

Conclusion

This

was a fun project, that did not require a lot of time or special supplies

or equipment. If I were to do it again. I would not use the provided visor,

but make my own. Also, having the helmet chromed would be a nice touch,

but expensive $65 to $100. More that the cost of the helmet and the paint!

For the prop maker on a budget this is a good alternative. Add a foam

sweatband, and cut the eye slot, and you can wear it!

References

the

following images are collected from the web. Try Google

image search for cylon.

Here

is an excellent reference page for a real Cylon!

Thanks Starbuck!

Links

KROPSERKEL

Prop collection page has good info on Cylons. Check out this page. www.kropserkel.com/cylon.htm

WeGottaFindEarth.com

Cylon suit reference

Page with images of a real Cylon suit and helmet.

www.battlestargalactica.org

offically liscensed BSG gear, although sometimes hard to get.

www.jcwhitney.com

Eye electronics source.

www.cylong.org

a Cylon news site.

Replica

Prop Forum - grandaddy of all prop collecting discussion boards. [membership

required]

www.ChrisPappas.com

- veteran collector of original BSG props.

Last

update: March 30, 2006

|